Valves Components and Operating Principle

As a common piece of equipment in fluid processing facilities, sanitary valves are different in types, shapes, and sizes. However, they all basically consist of some of the parts defined as follows:

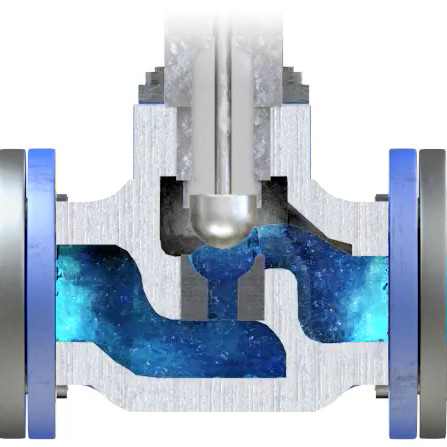

- Body: the framework that holds everything together and serves as the pressure boundary.

- Bonnet: the cover on the valve body. During valve manufacturing, the internal parts are put into the body and then the bonnet is attached to hold everything together inside. Some types of valves (ball valves for example) don’t have this part.

- Handle and Actuator: the handle is mainly used to manually open or close the valve; the actuator, pneumatic or electric, is used to automatically or remotely control the valve. Some valves, check valves, and relief valves, for example, have neither handle nor actuator because they automatically control themselves from the inside.

- Disc/Ball: a movable obstruction inside the body that controls the flow through the valve.

- Stem: the part that transmits the motion of the handle/actuator to the disc/ball.

- Packing: the seal between the stem and the bonnet that prevents leakage.

- Seat: the seating surface for the disc/ball.

Valves Operating Principle

Process plants consist of many control loops, networked together to produce a product. The control loops are devised to keep essential process variables such as fluid level, pressure, and temperature within the specified limit. This helps to ensure that the quality of the end product is as desired. Each of these loops creates internal disturbances that may affect the process variables.

Sensors and transmitters are used to collect information about the process variable. A control valve is an end device used to control the process based on this data. This helps to decide the course of action to get the process variable back to where it should be (set point).