The Sealing Performance of Stainless Steel Ball Valve

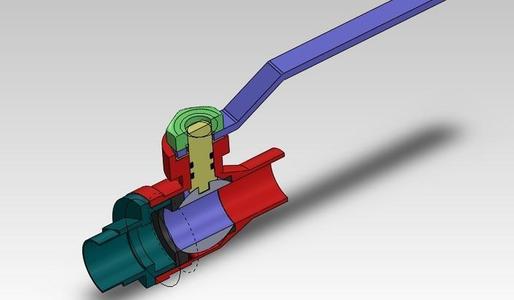

There are the reduced diameter and non-reduced diameter structures for sanitary ball valve. Regardless of the structure, the flow resistance coefficient of the ball valve is relatively small. In particular, for the so-called full-flow type, also known as non-reduced diameter ball valve, because its channel diameter is equal to the inner diameter of the pipe, and the partial resistance loss is the same as the friction resistance of pipeline of the same length.

Among all kinds of valves, the flow resistance of this kind of ball valve is the smallest. In the rocket launcher and its testing system, the resistance of the pipeline needs to be as small as possible. There are two ways to reduce the resistance of the pipeline system: one is to reduce the flow rate of the fluid, which requires the pipeline diameter and valve diameter to be increased.

This will often have adverse effects on the pipeline system, especially on low-temperature delivery systems. The other is to reduce the local resistance of the valve. Therefore, the ball valve naturally becomes the best choice.

The opening and closing of the valve are quick and convenient. As we only need to turn the handle by 90 degrees to complete the action of full opening and full closing, it’s very easy to achieve quick opening and closing. The opening and closing time of some structures is only 0.05~0.1 seconds. This is to ensure it can be used in the automation system of the testing pad. The operation doesn’t have an impact when quickly opening and closing the valve.

The sealing performance of the ball valve is good. Currently, the vast majority of the valve seat of the ball valve is made of PTFE and other elastic materials. The sealing pair composed of metal and non-metal materials are often called soft sealing. Generally speaking, the sealing performance of soft sealing is easy to be guaranteed. And the requirement for the processing precision of the sealing surface and surface roughness is not high.

The service life of the ball valve is long. It is because the PTFE has good self-lubricating properties and the friction loss with the ball is small. And because of the improvement in the processing technique of the ball, the roughness is reduced, thereby improving the service life of the ball valve.