Pressure Testing Methods for Diaphragm Valves

How Do Diaphragm Valves Work?

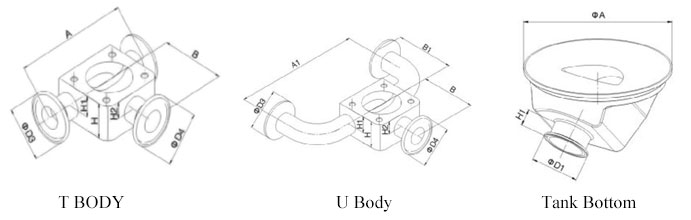

Sanitary diaphragm valves use a flexible diaphragm made of soft materials that separate the valve body cavity from the valve cover cavity. Diaphragm valves provide on/off throttling and bi-directional flow. They control flow rates by reducing or increasing the area that fluid can pass through. Performing various pressure testing methods for diaphragm valves before installing them is critical to the health and longevity of any fluid or gas system.

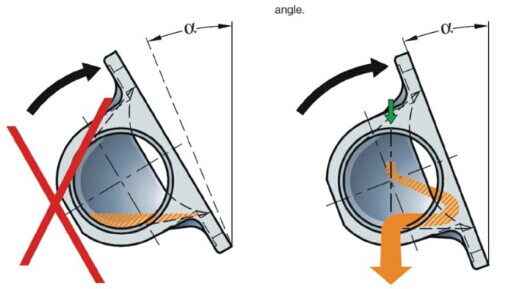

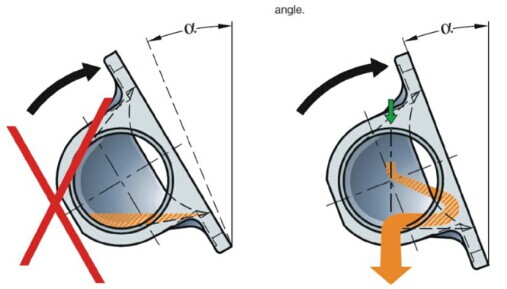

A diaphragm valve is actually nothing more than a “clamp” valve — an elastic diaphragm that is connected to the compression component by screws. The valve stem drives the compression component to move up and down. When the compression component moves up, the diaphragm rises, leading to an open channel. When the compression component moves down, the diaphragm is pressed against the valve body weir (assuming it is a weir valve) or pressed to the bottom of the structure (assuming it is a straight-through valve).

Diaphragm valves offer a distinct advantage — their main functional component is housed separately from the fluid passing through it. This helps ensure the purity of the fluid by diminishing contamination from corroded parts. It also makes the valve more dependable, as high-pressure fluids cannot damage the diaphragm, a problem seen in some other, more traditional valve types.

Pressure Testing Method for Diaphragm Valve

The strength test for diaphragm valves is very similar to the pressure testing methods for butterfly valves. First, introduce the medium from one end, open the valve flap, and keep the other end closed. Second, raise the test pressure to the specified value and then check for any leakage around the valve body and valve cover. If there are no leaks, then it’s considered qualified. Finally, depressurize the system to the sealing test pressure, close the valve disc, and open the other end for inspection. If there’s no leakage, then it’s considered qualified.

Pressure Testing Method for Diaphragm Valve

The diaphragm isolates the medium from the upper cavity of the valve stem, so even if there is no stuffing medium, there won’t be leakage. However, due to the limitations of the diaphragm and lining materials, the pressure resistance and temperature resistance are relatively poor. It is usually only suitable for occasions where the nominal pressure is 1.6MPa and the temperature is below 150 degrees Celsius.

How Do Diaphragm Valves Work?

What is a Diaphragm Valve Used for?

Diaphragm valves have a simple structure and low fluid resistance, making them suitable for switching and throttling. They offer a larger flow capacity compared with other valves of the same specifications. Their leak-free performance makes them perfect for the regulation of medium and high viscosity fluids and fluids with suspended solids.

Conclusion

The diaphragm valve is a relatively new and highly specialized type of block valve. Its opening and the closing diaphragm are made of softer materials, and separates the valve body cavity from the valve cover cavity and drive components. This diaphragm structure makes it a unique design with myriad applications and potential for more in the future. This helpful equipment is widely used in various fields, with the most commonly used diaphragm valves being rubber-lined diaphragm valves, fluorine-lined diaphragm valves, unlined diaphragm valves, and plastic diaphragm valves.