The Features of Knife-shaped Gate Valve

Knife-shaped gate valve has the advantages of simple structure, reasonable design, light material, reliable sealing, light and flexible operation, small size, smooth channel, small flow resistance, lightweight, easy installation, and easy disassembly.

This completely solves the problem of heavyweight, large flow resistance, large area, and difficult installation commonly found in ordinary gate valves, plate gate valves, shut-off valves, regulating valves, butterfly valves, sanitary ball valves, and other valves. It can replace the generic shut-off valve and regulating valve, and can normally work under the working pressure of 1.0MPa~2.5MPa and an operating temperature of -29~550 degrees Celsius.

The gate plate of the knife-shaped gate valve has a shearing function, which can scratch the adhesive on the sealing surface and automatically remove the debris. Stainless steel gate plates can prevent sealing leakage caused by corrosion.

Knife-shaped gate valve is suitable for the coal preparation and slagging of coal mine power plant, urban sewage treatment, food, paper, medicine, petroleum, chemical and other oil, water, steam pipe, cement slurry, slag, slime, pulp, wood pulp, tailings, fiber, dust, sewage of chemical treatment, sedimentation tanks, asphalt, silo outlets, fruit, grain, slaughterhouse wastewater, and other media.

Knife-shaped gate valve has the following features:

1. Liftable gate plate sealing surface, which can scratch the adhesive off the sealing surface and automatically remove the debris.

2. Stainless steel gate plate can prevent sealing leakage caused by corrosion. Fine grinding and polishing can get a better sealing effect. The bottom of the blade is machined into a knife-like shape, which has a cutting function for soft materials such as fiber, pulp, and wood pulp, as well as a good opening and closing effect. The upper end of the knife board is installed with a hard PTFE scraper, which can prevent dust, gravel, and other material with scratching features from entering the packing box. This can significantly improve the service life of the knife board.

3. The stainless steel valve body is durable. The enhanced valve body design improves the strength of the valve body. The use of double snail makes the opening and closing more quickly.

4. Overall stainless steel materials can prevent damage from corrosion. The valve body and stuffing are both finely cast. According to user needs, the materials can be 304, 316, 316L, WCB, 2Crl3. The sealing ring uses enhanced PTFE, which is corrosion-resistant, wear-resistant, and residue-free.

5. Full round direct flow channel doesn’t keep debris and doesn’t jam.

6. Scientific upper sealing stuffing design makes the upper sealing safe, effective and durable.

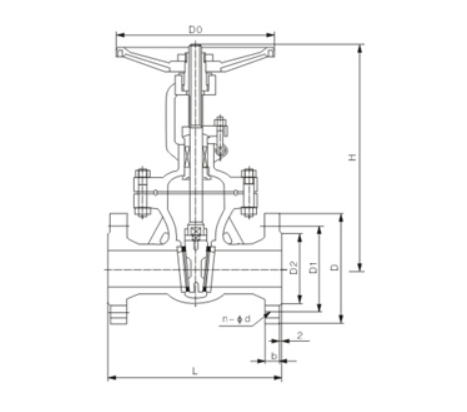

7. Short structural length can save raw materials and installation space, while effectively supporting the pipeline strength.

8. Triangle stent saves raw materials, ensuring the required mechanical properties.

9. The guide block on the valve body of the knife-shaped gate valve makes the gate plate move correctly. The squeeze block ensures effective sealing of the gate plate.

10. Knife-shaped gate valves can also arbitrarily choose actuators.

11. A V-shaped gate plate can be used as a regulating valve.

12. Compact design, small size, lightweight, low price, easy installation, perfect wear-resistant and anti-blocking mechanism, easy maintenance, easy use, and long service life. Also, the actuators can be arbitrarily chosen.

13. The valve plate has five supporting points, which make the valve plate have good self-centering. When the valve is closed and sustains the backpressure, the valve plate doesn’t dislocate.