The Features and Performance of Butterfly Valve

What is a Butterfly valve?

Butterfly valve is a kind of valve whose opening and closing member (valve flap or butterfly plate) is a disc, which rotates around the valve shaft to achieve opening and closing. It is mainly used in the pipeline for shutting off and throttling.

From the state of being fully open to the state of being fully closed, sanitary butterfly valve is usually less than 90 degrees. Butterfly valve and butterfly stem themselves don’t have self-locking abilities. For the positioning of the butterfly plate, a worm wheel decelerator needs to be installed on the valve stem. The use of a worm wheel decelerator can not only make the butterfly plate have self-locking abilities and stop at any position, but also improve the operational performance of the valve.

What is a sanitary butterfly valve?

The sanitary butterfly valve is characterized by its high-temperature resistance. The applicable range of pressure is also relatively high. The nominal diameter of the valve is large. The valve body is made of carbon steel. The sealing ring of the valve plate uses a metal ring instead of a rubber ring. Large-scale high-temperature butterfly valve uses steel plate for welding and manufacturing. It is mainly used in the smoke duct and gas pipelines of the high-temperature medium.

What are the advantages of butterfly valves?

The advantages of butterfly valves are as follows:

1. Easy and quick opening and closing. Small fluid resistance. It can be frequently operated.

2. Simple structure, small size, and lightweight.

3. It can transmit mud, and has the least amount of liquid accumulated at the outlet of the pipeline.

4. Under low pressure, good sealing can be achieved.

5. Good regulating performance.

What are the shortcomings of butterfly valves?

The shortcomings of the butterfly valve are as follows:

1. The range of operating pressure and temperature is small.

2. Poor sealing.

What are the types of butterfly valves?

According to the structural type, butterfly valve can be divided into bias plate, vertical plate, inclined plate and lever. According to the sealing type, it can be divided into soft-sealing and hard sealing. Rubber ring sealing is usually used in soft-sealing types. Metal ring sealing is usually used in heat sealing types. According to the connection type, it can be divided into flange connection and clamp connection. According to the transmission type, it can be divided into manual, gear transmission, pneumatic, hydraulic, and electric types.

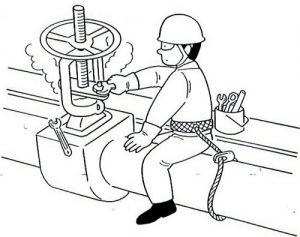

How to install and maintain the butterfly valve?

For the installation and maintenance of the butterfly valve, the following should be noted:

1. During installation, the valve flap needs to stop in the closed position.

2. The opening position should be determined by the rotation angle of the butterfly plate.

3. For a butterfly valve with a bypass valve, open the bypass valve before opening the butterfly valve.

4. The installation should be performed according to the manufacturer’s installation instructions. For a heavy butterfly valve, a solid foundation should be set up.