7 Advantages of Vacuum Shut-off Valves

What is a Vacuum Valve?

A vacuum valve refers to the vacuum system components used to change airflow direction, adjust the airflow, cut off, or connect a pipeline in a vacuum system. It refers to valves with working pressure below standard atmospheric pressure. Vacuum valve components are sealed with a rubber sealing ring or metal sealing ring to maintain the dependable vacuum-seal closure that they’re named for.

Advantages of Vacuum Shut-off Valve

What is the Purpose of a Shut Off Valve?

A vacuum sanitary shut-off valve is mainly used in pipelines to shut off, distribute, and change the flow direction of the fluid medium. They can also be used to protect the vacuum system in power failure situations.

What is a Vacuum Shut-off Valve?

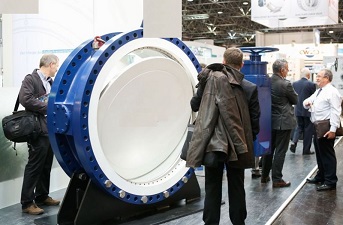

The vacuum shut-off valve is a relatively new type of gate valve. It has some unique advantages inherent in its structure, such as durable sealing and low-torque, frictionless opening and closing. This can reduce the total pressure on the associated actuator. Using a multi-turn electric actuator can help achieve efficient regulation and shut-off for most fluid processing systems. It’s widely used in petroleum, chemical, urban water supply, drainage, and other working conditions that require consistently dependable shut-off performance. This type of valve is usually installed horizontally.

What are the Advantages of Vacuum Shut-off Valves?

Vacuum shut-off valves are essential components of numerous fluid processing systems. These specialized valves offer the following advantages:

1. Low Fluid Resistance

Its resistance coefficient is equal to that of the pipe segment of the same length.

2. Efficient Performance

The lightweight and compact size make it a convenient fit on most fluid process systems and, therefore, easy to install.

3. Tighter Sealing

Currently, plastics are used for most gate valve sealing surfaces, which provide sufficient sealing for vacuum applications.

4. Easy Operation

It only takes a rotation of 90 degrees to switch from the fully open state to the fully closed state, making it the fastest and most convenient option whether you use manual control or remote control.

5. Easy to Repair

The gate valve has a simple structure with a sealing ring that usually remains activated, making it convenient to disassemble and replace when necessary.

6. Erosion-Free Performance

Fluid cannot erode the sealing surface as it passes through the valve. When it’s fully open or fully closed, the gate body’s sealing surface and valve seat are isolated from the fluid medium. This helps extend the longevity of the entire valve and ensures consistent sealing over its lifetime.

7. Wide Range of Application

A vacuum shutoff valve can be made with a diameter as small as a few millimeters or as large as a few meters. It can be applied to fluid systems with diverse demands, from high vacuum to high pressure. Plus, its reliable performance makes it perfect for emergency shutoff use.

Conclusion

Vacuum shutoff valves have become essential gate valves in various fluid process systems thanks to their dependable vacuum sealing. They offer several advantages that make them beneficial in many highly specialized applications.