AV-3F Sanitary Flange Connected Check Valves with Welded Ends

Specifications

| Size | 1”, 1.5”, 2”, 2.5”, 3”, 4” |

| Max. working temperature | 140°C |

| Max. working pressure | 10 Bar |

| Body material | 316L/304 |

| Sealing material | VITON, SILICON, EPDM |

| Connection | Welded, thread, clamp |

| Finishing | Ra<0.8μm |

| Standards | ISO/DIN/ASME BPE/3A/BS/GB |

Sanitary Flange Connected Check Valves with Welded Ends Description

The Sanitary Flange Connected Check Valves with Welded Ends is very useful and has been widely used in industry and our everyday life. Founded in 2002, Adamant Valves has become a global sanitary valves manufacturer and valves supplier. As one of the leading valves manufacturers, Adamant Valves provides customers with high-precision Sanitary Flange Connected Check Valves with Welded Ends at a very affordable price.

Sanitary Flange Connected Check Valves with Welded Ends Specifications

| Size | 1”, 1.5”, 2”, 2.5”, 3”, 4” |

| Max. working temperature | 140°C |

| Max. working pressure | 10 Bar |

| Body material | 316L/304 |

| Sealing material | VITON, SILICON, EPDM |

| Connection | Welded, thread, clamp |

| Finishing | Ra<0.8μm |

| Standards | ISO/DIN/ASME BPE/3A/BS/GB |

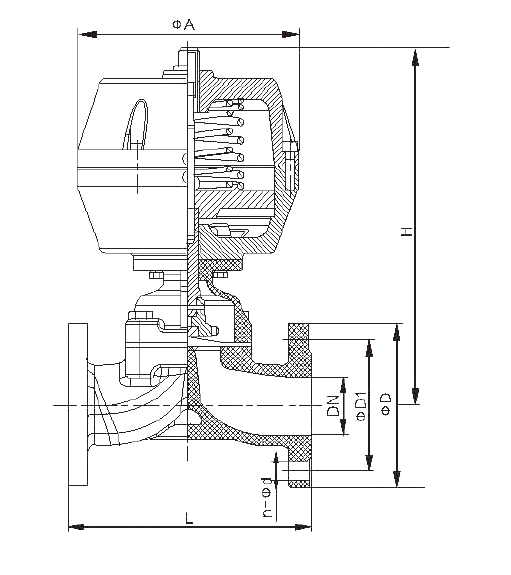

| Size | L | A | B | T |

| 0.5″ | 100 | 12.7 | 9.4 | 1.65 |

| 0.75″ | 100 | 19.1 | 15.8 | 1.65 |

| 1″ | 112 | 25.4 | 22.1 | 1.65 |

| 1.5″ | 115 | 38.1 | 34.8 | 1.65 |

| 2″ | 115 | 50.8 | 47.5 | 1.65 |

Sanitary Flange Connected Check Valves with Welded Ends Options

– Connections: Butt-weld, sanitary clamp, flange, thread, etc. (DIN, IDF, SMS, RJT, 3A standard)

– Seals and gaskets: EPDM as default, Silicone or Viton (FPM) are available upon request.

– Pressure range adjustable (by calibrating spring).

Sanitary Flange Connected Check Valves with Welded Ends Applications

- Food industries

- Personal care industries

- Pharmaceuticals industries

Reviews