Sanitary Butterfly Valves Manufacturing Requisitions

Hygiene is paramount in all food processing plants. Having the right tools for your machine is paramount to ensure that you produce high-quality food or substances and, of course, pleasant quantities.

Sanitary valves are a crucial percentage in processing plants and food industries, as they are obligatory routes for almost all elements. In addition to everyday industry, sanitary valves can be used in many other fields and are used in many activities, such as agribusiness, pharmaceuticals, the chemical industry, biotechnology and cosmetics, the medical sector, and the medical industry, as well as in the processing of wastewater.

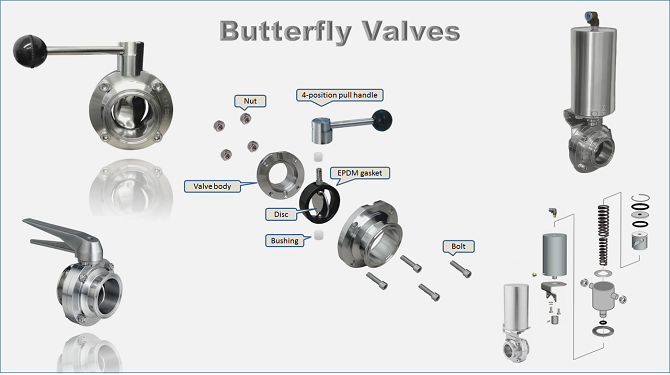

The manufacturers of sanitary butterfly valves make sure that they have considered the most appropriate characteristics in the manufacture of valves that will be used in the food industry.

They follow all hygiene precautions from the material selection step to the final polishing point. Therefore, you have the security of having clean, polished, hermetic valves, without leaks and non-corrosive at the time of purchase.

Various materials are used to make the valves and you can choose according to your individual specifications and the machine you are using.

The material used is well analyzed and is regulated by ISO or FDA to ensure that toxic materials do not enter the market. Manufacturers are aware of this and involve experts in the material analysis process. Most materials are plastic and metal.

Therefore, the expectations and requirements of the customer are the first in the manufacturing process, so the valves are manufactured using the latest technology and the most standard techniques that guarantee durability, the value of your money, and the satisfaction of the clients.

Most valves are operated manually, hydraulically, and also pneumatically, which increases the operating capacity and flexibility of the valves to accommodate several machines without complications and maximize performance.

This element guarantees high performance and maximum functional capacity. Commonly, stainless steel and other metals such as ductile iron are used to make valves.

The stainless steel material allows easy cleaning and maintenance of these devices. Sanitary valve manufacturers ensure that they comply with the legal guidelines required to ensure efficiency and maximize machine performance.