Main Performances of Sanitary Ball Valves

The main function of the sanitary ball valve is to cut off and connect the fluid in the pipe, and the ball valve has the characteristics of small fluid resistance, good sealing, quick switch, and high reliability. The two main performances of sanitary ball valves are strength and seal.

Strength properties

The strong performance of sanitary ball valves is the capacity of the valves to withstand medium pressure. The valve is a mechanical product that bears internal pressure, so it must have sufficient strength and stiffness to ensure long-term use without rupture or deformation.

Sealing performance

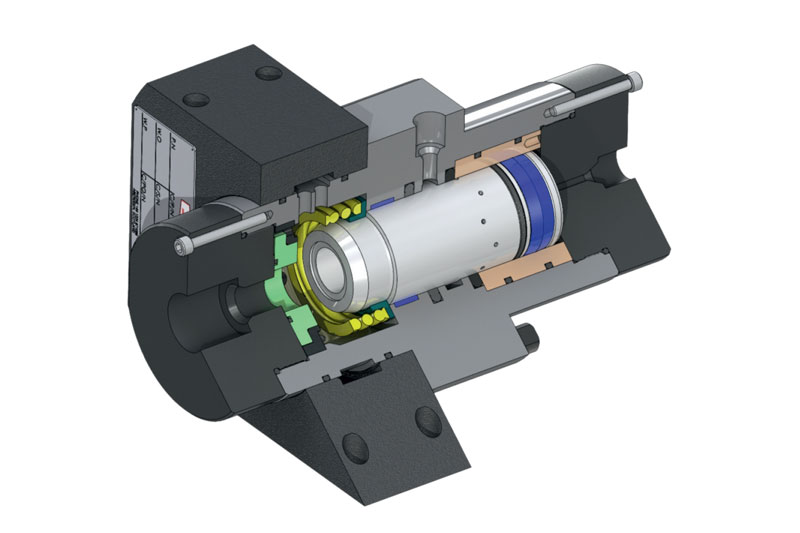

The sealing performance of the valve refers back to the capability of all sealing elements of the valve to save you the leakage of media, which is the most critical technical performance index of the valve. There are 3 sealing elements of the valve. The primary is the contact between the outlet and closing components and the sealing cover of the valve seat; the second one is the matching between packing and stem and stuffing container; the last is the relationship between the valve body and the cover.

The first leak in these sealing elements is called an internal leak, that’s frequently referred to as a loose closure and influences the valve’s potential to cut off the medium. Inner leakage isn’t allowed for intercepting valves. The latter leaks are called leakage, in which the medium leaks from the internal to the out of doors of the valve. Leakage will reason cloth loss and environmental pollutants, even extreme injuries. Leakage isn’t always allowed for inflammable, explosive, poisonous, or radioactive media, so the valve has to have reliable sealing performance.

The following points should be noted when installing sanitary ball valves.

*During the construction, the construction contractor, the safety department, the factory production department and the construction unit shall fully coordinate to clarify the scope of responsibility for the operation;

*The full-time responsible person shall work on the site in the respective work responsibility area;

*When removing or installing sanitary valves, make changes and arrangements for daily production within a certain range affected by this operation, then remove and cut off the medium in the pipe;

*Support to fit the weight of the sanitary valve should be provided at the worksite to prevent the sanitary valve from sinking and the center of the piping;

*After the completion of the work, the company should prepare for the pressure test, airtightness test, non-destructive inspection, and other inspection items;

*Before entering the production operation at the end of the operation, the inner cleaning of the pipe network should be carried out, the removal of the blind plate on the pipe should be confirmed, and the operated valve should be restored to the open and close state before construction.