Introduction of Oil Lubricated Hard Sealing Plug Valve

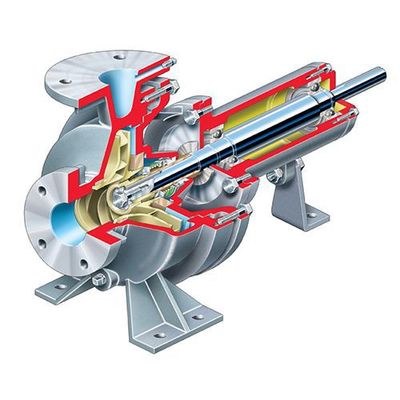

Oil-lubricated hard sealing plug valve can be divided into conventional oil-lubricated plug valve and pressure-balanced plug valve. Special lubricating grease is instilled into the space between the cone hole and the plug body of sanitary valve body from the top of the plug body, forming oil film to reduce the opening and closing torque of the valve and to improve sealing performance and service life. Its working pressure can be up to 64MPa. Its maximum working temperature can be up to 325 degrees Celsius. Its maximum caliber can be up to 600 mm.

1. Conventional oil-lubricated plug valve

1) For conventional hard sealing plug valve, the installation method of plug cone body is positive. In order to reduce the friction between the valve body and the plug sealing surface, the valve usually uses the sealing structure that uses sealing grease to lubricate the valve seat. The high-pressure sealing oil injected from the high-pressure oil nozzle forms a high-pressure sealing ring around the plug. There is a layer of oil film between the valve body and the sealing surface of plug cone, which can be closed and lubricated.

2) In order to further reduce the opening and closing torque of the plug valve, we often reduce the diameter of the plug. Therefore, plug valve usually uses a rectangular flow channel. While reducing the opening and closing torque of the plug valve, this method increases the fluid resistance of the plug valve.

3) The plug cone sealing part is soldered with STL alloy material or uses surface hardening technology to enhance sealing surface’s wear-resistant and corrosion-resistant abilities. The service life is long.

4) The surface of the plug cone is ground to mirror surface, which has a lower opening and closing torque.

2. Pressure-balanced plug valve

In order to reduce the torque of conventional hard sealing plug valves, a Pressure-balanced plug valve is often used. In addition to having the characteristics of conventional oil-lubricated plug valve, pressure-balanced plug valve also has the following characteristics:

1) The installation method of plug cone of pressure-balanced plug valve is in reverse mode. There is a check valve at the upper part of the plug cone. When the valve is closed, due to the difference in upper and lower cross-sectional area of the plug cone, the injected high-pressure sealing oil gives the plug body a lifting force, which can better seal the sealing surface of the plug body and valve.

2) At the moment the valve is opened, the pressure in the lower chamber of the valve body is balanced with the pressure of the medium in the pipe. The high-pressure sealing oil in the upper chamber of the valve body makes the plug body be subject to a downward thrust so that there’s a slight gap between the plug cone and the sealing surface of the valve body. This can effectively reduce the torque when rotating the plug body. The sealing pair can also be protected.

3) Under high temperature working conditions, the thermal expansion of the plug can be absorbed by its lifting to avoid the wedging of the sealing pair.

For an oil-lubricated hard sealing plug valve, although the use of oil lubrication can reduce the opening and closing torque to a certain degree, it may pollute the medium. Therefore, please choose sealing lubricants according to the actual working conditions.