How Can Sanitary Diaphragm Valves Be Used Properly?

Sanitary diaphragm valve is a clamping type valve, which is mainly used for opening and closing the pipe. The sanitary diaphragm valve has two main advantages, one is that the valve does not require a separate stem packing seal structure, and the diaphragm acts as a stem seal while cutting off the medium; the other is that the flexible diaphragm is reliable enough to shut off even the liquid.

Therefore, the control mechanism is completely separated from the media channel, making the diaphragm valve applicable not only to the food industry and medical and health industry but also to some difficult transmission mediums and dangerous mediums.

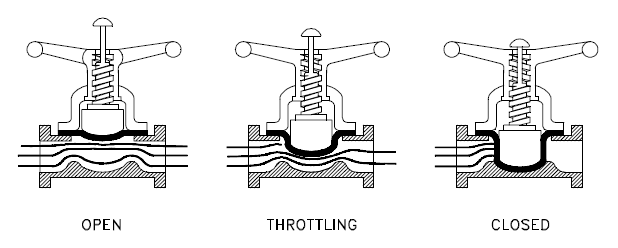

Generally, sanitary diaphragm valves are recommended for use under conditions of service or for media requiring strict sealing performance, mud medium, abrasion, lightweight construction, low-pressure cut-off (small pressure difference), small leakage to the atmosphere, and abrasion; Besides, diaphragm valves can also be used on the occasion of double adjustment, throttling, channel constriction, low noise, cavitation and vaporization, and small operating torque; Under the conditions of high-temperature medium, high-pressure medium, high-pressure cut-off (large pressure difference), quick opening and closing and short structure length, diaphragm valve is not selected, except for metal diaphragm valve.

Due to the structural design of the diaphragm valve itself, it is particularly suitable for ultra-pure media or highly polluting, highly viscous liquids, gases, corrosive or inert media. When combined with control equipment, a diaphragm valve can replace other traditional control systems, especially for solid and non-polluting inert media. The sanitary diaphragm valve operating mechanism in the pipeline is not exposed to the transport fluid, so it is not polluting and does not require packing, and the stem packing part is not likely to leak. Therefore, diaphragm valves are specially designed for transporting corrosive, viscous fluids, such as mud, food, medicine, and woven adhesives.

The metal sanitary diaphragm valve is constructed by clamping a thin, semispherical sheet of metal into the body as a barrier between the stem and the fluid. The valve closing is achieved by pressing the disc onto the seat through the stem head and metal film, while the valve is opened by an internal spring and the disc rises when the stem rises and disengages in contact with the membrane. There is no direct contact between the stem and the disc, and the disc does not pass through the stem leaving the seat, so this valve is used in a differential one-way flow and is usually “under the seat”.However, a large amount of backflow should be avoided in use, so as not to affect valve closure.

Generally speaking, it is economical and effective to select a metal diaphragm valve under high temperature and high pressure. This valve can also be used at low temperature and low pressure when a synthetic rubber diaphragm valve is not desired.