Factors to Consider When Selecting Sanitary Relief Valves

Several factors must be taken into account when selecting appropriate relief valves for an application. Here are some of them:

1. The size of the pipe in the system: This is of utmost importance because the size of the pipe will determine the size and even the type of pressure relief valve to be used in the piping system.

2. Setting pressure: This is crucial in determining the type of pressure relief valve for an application because; the differential pressure affects the sealing ability.

3. Temperature: This affects the material of the bodies of the various components of the piping system. The component materials used in high and low temperatures are different.

Materials with varying expansion rates can allow fluids to leak. Plastics can shrink, leak, absorb water or other media and become very fragile at low temperatures. Elastomers have a high coefficient of thermal expansion and can crack and harden in cryogenic service.

4. Type of: The pressure relief valves are of two main types:

• The “safety” or “pop-off” valve

This valve opens fully when the set pressure is reached. It then diverts all or almost all the flow through the discharge port of the valve.

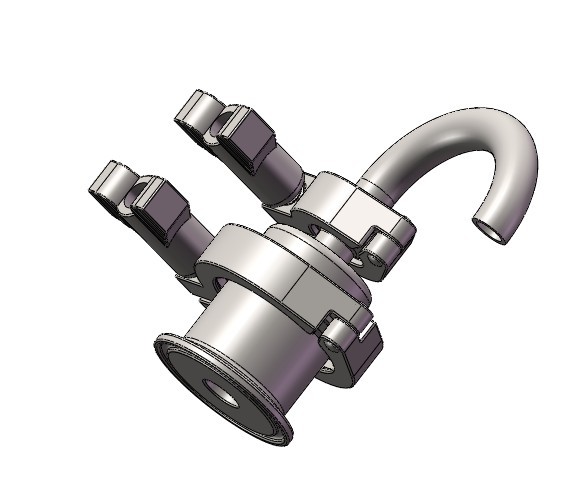

• The type that pressure is relieved gradually diverts flow from the discharge port.

This valve functions as both a pressure limiter and a flow control valve. Here, a spring pushes a piston on a seat that is down. The pressure gradually exceeds the set pressure, moving the piston away from the seat and the flow is gradually directed outward through the discharge port. When the system pressure continues to rise above the set pressure, the flow is diverted. The maximum discharge rate is reached when the piston is furthest away. These pressure relief valves are used for flow control as well as for pressure control.