What Should be Done if the Sanitary Fittings Deform?

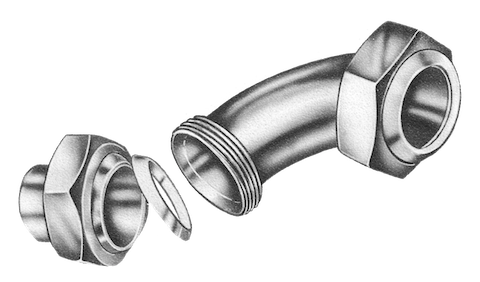

Sanitary fittings are the parts that connect pipes into pipes and are made of stainless steel, and they can be divided into welding type, clamping type, and thread type connection according to the connection method. Sanitary fittings are often used in pharmaceutical, food, and other industries where the sanitary grade is very high.

Generally, those who purchase sanitary fittings are pharmaceutical or food factories for maintenance and the configuration of related equipment. Buyers are basically pharmaceutical and food equipment system integrators and wholesalers.

However, deformation of sanitary fitting may occur occasionally in the process of application. There are many reasons for the fitting deformation, and the first is that quality involves raw materials, process equipment, mold, operation process, and so on.

At present, the biggest quality problem of injection molding water supply and drainage pipe fittings in domestic and foreign markets is the poor stability of matching size, the inner wall has silver silk lines, internal stress cracking, uneven wall thickness, the loss of circular orifice leads to the butt joint of pipe fittings is difficult, butt welding overlap area is small, easy to leak, etc.

All sanitary fittings should be used and maintained in a correct and reasonable manner so that the service time can be prolonged. Below are some tips on how to avoid the deformation of sanitary fittings.

* Sanitary ball valve, sanitary globe valve, and sanitary gate valve should only be fully open or fully closed when in use. It is not allowed to adjust the flow rate to avoid erosion of the sealing surface and accelerated wear. The gate valve and upper thread globe valve have the reverse sealing device, and the handwheel is rotated to the top position to tighten to prevent the media from leaking from the packing.

* The sanitary fittings can be directly installed on the pipeline according to the connection mode and the position of use. In general, it can be installed in any position in the pipeline. However, in order to facilitate the inspection of the operation, it is necessary to pay attention to the cut-off stainless steel elbow media flow should be longitudinal disc below the upstream, so that the size of the stainless steel head can only be installed horizontally. Pay attention to the sealing of pipe fittings during installation to prevent leakage and affect the normal operation of the pipe.

* Long-term storage of pipe fittings should be checked on schedule, the surface of the exposed processing must be kept clean, remove dirt, and neatly stored in an indoor air dry place.