Sanitary Diaphragm Valves With High Sanitary Requirements

Sanitary diaphragm valves refer to valve fittings used in pharmaceutical, food, and other industries, as well as in places where sanitary requirements are very high. Generally, the purchasers of sanitary diaphragm valves are basically pharmaceutical and food equipment system integrators and wholesale buyers.

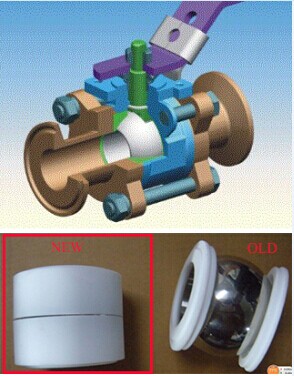

Operation structure

A Sanitary diaphragm valve can be used for access to wine, vinegar, and other liquids. It consists of two parts, the upper part is the opening and closing plate, while the lower part is divided into the main body, and the main body is composed of the cover, the main shell, and the valve core. An air hole is arranged on the wall of the liquid outlet pipe of the main housing. One end of the air hole is connected with a gas pipe, and the other end is connected to the air. A pull rod is fixed in the spool, a spring seat is arranged on the spool, and spring is placed on the spring seat. The opening and closing plate are placed on the cover of the main body, and they are connected with a pull rod, and a handle and a vent plug are fixed on the opening and closing plate.

The Sanitary diaphragm valve is operated by remote control or manual operation through the handle of the driving device. The driving device has three standards: normally closed type, normally open type, and pneumatic type. It has the advantages of simple structure, beautiful shape, quick disassembly and assembly, flexible operation, small fluid resistance, and safe and reliable use, which is widely used in the control of water, gas, oil, and corrosive medium in chemical, petroleum, metallurgy, water heating, food, medicine, and other industries.

Working principle

The tight fit of the body and diaphragm of the sanitary diaphragm valve provides a body seal and seat seal, ensuring complete isolation of the internal and external environment of the pipe, so the sanitary diaphragm valve is suitable for the sterile process. The sanitary diaphragm valve opens and closes by moving the stem up and down. When the sanitary diaphragm stem is in the upper position, the spherical diaphragm bends upward to form a conducting state of the valve; as the stem moves up and down the spool causes the diaphragm to bend, forcing the diaphragm to press against the seating area or shut off the path of pipe flow.

Sanitary diaphragm valves can be operated manually or pneumatically and can be controlled by an intelligent controller. It is very suitable for pipe fluid control and on/off tasks, so it is also widely used in the health level of wine, dairy, beverage, and other food industries and the pharmaceutical field of aseptic conditions.

Suitable for ultra-pure, corrosive, and inert medium

As the working medium is only in contact with the diaphragm and valve body of the sanitary diaphragm valve, both of which can be used in a variety of different materials, the valve can ideally control a variety of working media. Sanitary diaphragm valves are especially suitable for media with chemical corrosion or suspended particles. The working temperature of the diaphragm valve is usually limited by the diaphragm and body lining material used, its working temperature range is about – 50 ~ 175 ℃.

A Sanitary diaphragm valve is used in pharmaceutical, biological, purified water treatment, and other places with higher health requirements. The structure design of the diaphragm valve itself is particularly suitable for ultra-pure medium or serious pollution, very viscous liquid, gas, corrosive or inert medium. When combined with control equipment, the diaphragm valve can replace other traditional control systems, especially for solid and easy to pollute the inert medium, and the diaphragm film can be replaced after long-term use.