AV-5DS Sanitary Double Seat Mix Proof Valves

Materials

Materials: AISI-316L, AISI 304

Size: 1”-4”

Seal: PTFE

Options: Silicone, EPDM, Viton

Lip seal & Seal ring: EPDM

Options: Viton, Silicone

Other seals: EPDM, all seals complying with FDA21CFR177.2600

Standard Design

- forged spherical body

- Compact design

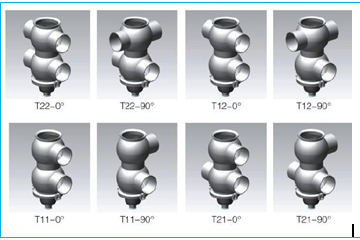

- 360 degree orientation

- Mix-proof design, the bodies can be with different diameters.

- Over-pressure protection design preventing the pressure fluctuate to 30bar

- Easy disassembly

- Seat lift type and cavity spray type available

Sanitary Double Seat Mix Proof Valves Application

AV-5DS series sanitary double-seat mix-proof valve has been designed to allow safe separation of non compatible products (such as milk or milk products & cleaning solution) and to allow one housing of the valve and the corresponding valve seat as well as the vent cavity to be cleaned while milk or milk products are present in the opposite valve housing and line. The series includes 2 types: Seat lift type and Cavity spray type.

Sanitary Double Seat Mix Proof Valves Materials

Materials: AISI-316L, AISI 304

Size: 1”-4”

Seal: PTFE

Options: Silicone, EPDM, Viton

Lip seal & Seal ring: EPDM

Options: Viton, Silicone

Other seals: EPDM, all seals complying with FDA21CFR177.2600

Sanitary Double Seat Mix Proof Valves Video

Sanitary Double Seat Mix Proof Valves Standard Design

- forged spherical body

- Compact design

- 360 degree orientation

- Mix-proof design, the bodies can be with different diameters.

- Over-pressure protection design preventing the pressure fluctuates to 30bar

- Easy disassembly

- Seat lift type and cavity spray type available

Sanitary Double Seat Mix Proof Valves Actuators

Normally Closed (NC) – Air to open and spring to close;

Normally Open (NO) – Air to close and spring to open;

Air to Air (AA) – Air to open air to close.

Sanitary Double Seat Mix Proof Valves Technical Specification

- Size available: DN25-1″ to DN100-4″

- Max. working pressure: 145psi (10bar)

- Control air pressure: 70 ~ 102psi (5 ~ 7bar)

- Working temperature range: EPDM: 14 ~ 248°F (-10 ~ 120°C)

- Sterilization temperature: 302°F (150°C, Max. 20 min)

- Pneumatic connection: G1/8″ (BSP)

- End connections: butt-welded, sanitary clamp, threaded, flange, DIN, SMS, RJT, IDF, or others upon request.

- Finish: <32Ra (<0.8µm); Other finishes available upon request.

Technical Parameters |

|||

| Steel material | Product wetted steel parts | AISI 316L, AISI 304 | Provided with material inspection report |

| Other steel parts | AISI 304 | ||

| Seal material | Standard | PTFE | All seal materials comply with FDA 21CFR117.2600 |

| Options | FPM, Silicone, EPDM | ||

| Pressure | Working pressure | 0 ~ 145psi (0 ~ 10bar) | |

| Supply pressure for air actuator | 5 ~ 7bar (70 ~ 102psi) | ||

| Temperature | Working temperature | -20 ~ 350°F (PTFE) | |

| Surface treatment | Inside surface treatment | Ra 16 ~ 32µin (0.4 ~ 0.8µm) | |

| Outside surface treatment | Matte | ||

| Connection | End connections: threaded, BSP / BSTP / NPT, clamp, flange or other upon request. | ||

| Pneumatic head | Normally Closed (NC) – Air to open and spring to close; Normally Open (NO) – Air to close and spring to open; Air to Air (AA) – Air to open, air to close. |

||

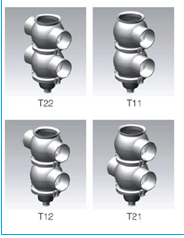

Valve Body Type

Clamped body combination One-piece valve body

Reviews