How do Sanitary Check Valves Work in Hot Water Heating System

Sanitary check valves are valves designed to prevent backflow of the medium in pipes or equipment, and they are opened using the kinetic energy of the fluid. In a heating system, check valves are usually installed at the pump outlet and other locations where the fluid is not allowed to flow in reverse.

4 types of sanitary check valves

* Lifting sanitary check valve

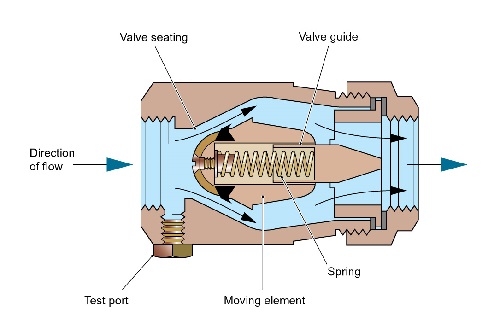

Lifting sanitary check valves are generally similar in structure to globe valves, with the disc moving up and down along the channel. It is reliable in action but has high fluid resistance and is suitable for small and light caliber applications. Lifting check valves are available in straight and vertical styles. Straight check valves can only be installed in the horizontal line, while vertical check valves are generally installed in the vertical line.

* Swing health check valve

The disc of the swing health check valve rotates around the shaft, and its fluid resistance is generally less than that of the lift check valve, so it is suitable for larger caliber applications. According to the number of the disc, swing check valves can be divided into three types: single disc swing, double-disc swing, and multiple disc swing.

Single disc swing check valves are generally used for medium-sized applications. When the single disc swing check valve is used in a large diameter pipeline, the slow closing check valve which can reduce water hammer pressure is preferred to reduce water hammer pressure. The double-disc swing check valve is suitable for medium and large-diameter pipelines, and the double-disc swing check valve with a small structure and lightweight is a fast development of the check valve. The multi-disc swing check valve is suitable for large diameter pipelines.

* Butterfly sanitary check valve

The structure of the butterfly sanitary check valve is similar to that of the sanitary butterfly valve. It is characterized by a simple structure, low flow resistance, and low water hammer pressure.

* Diaphragm check valve

The diaphragm check valve has a variety of structural forms, using the diaphragm as the opening and closing. Due to its good waterproof hammer performance, simple structure, and low cost, diaphragm valves have developed rapidly in recent years. However, the temperature and pressure of the diaphragm check are limited by the diaphragm material.

Application in a hot water heating system

Choosing the right type of check valve has a great influence on the protection of the water hammers. For example, a large number of water hammer accidents in the pump station are related to the check valve installed at the pump outlet. After the accident stops the pump, the water starts to flow back through the pump.

Under the action of the backflow, the check valve closes quickly. If the check valve is affected by the failure or bearing friction and its inertia, it may lag behind the time of starting the reverse flow, that is, when the backflow increases to a certain value, or even a quick shutdown at the moment of maximum backflow, high pressure can be generated at the check valve.

Shut-off of sanitary check discs is best when the flow rate is zero, but it is unlikely to be completed when the flow rate is zero. It is generally believed that as long as closed near zero flow is normal.

In the hot water heating system, the pressure pipe of the circulating pump can be set between the pressure pipe and the suction pipe in order to reduce the emergency stop pump water hammer. When the circulating pump is running, the check valve is closed because the water pressure on the outlet side of the pump is higher than that on the suction side.

When the pump stops suddenly, the pressure on the waterside of the pump decreases sharply, while the pressure on the waterside of the pump increases sharply. Under the action of this pressure difference, the water in the suction side pipeline of the circulating pump pushes the check valve to the water outlet side of the pipe network system, thus, the increase of pressure in the suction side pipe network is reduced, and the harm of water hammer is reduced and prevented.