Category: Valve Operation

Features of the Valve Manufacturing Process

Valves seem like fairly uncomplicated equipment in the machinery industry, right? They simply open and close to start and stop the flow of fluids and other mediums. They must be fairly easy to manufacture, right? When you take a closer look, you’ll find that every residential and industrial pipeline system would immediately fail without functioning […]

Read moreWhat Does the Operating Condition of Sanitary Valves Depend?

The working condition of the sanitary valve depends on many factors, including working pressure and working temperature of the medium, variation of pressure and temperature, driving mode, the installation position of the sanitary valve, service cycle, etc. Working pressure and temperature Generally speaking, the higher the pressure and temperature of the sanitary valve, the worse the […]

Read moreThe Causes Leading to Damaged Valve Sealing Surface

Mechanical damage: There will be scratches, bumps, crushes, and other damages during the opening and closing of the sealing surface. Between two sealing surfaces, under high temperature and high pressure, there will be mutual penetration of atoms, resulting in adhesion. When the two sealing surfaces move along each other, they’re prone to be torn apart […]

Read moreWhat is a Hydraulic Control Valve Mechanism?

What are the functions of the hydraulic control valves? Hydraulic control valves are used to adjust the flow rate of hydraulic fluid in a hydraulic system. These valves have a port that is able to be adjusted so that the flow area may be changed to provide an alteration in the flow rate through the […]

Read moreWhat Are the Anti-corrosion Methods for Sanitary Valves?

Coating The coating is the most widely used anti-corrosion means, especially in sanitary valve products is an indispensable anti-corrosion material and identification sign. The coating is usually made of synthetic resin, rubber slurry, vegetable oil, and solvent, covering the metal surface, insulating medium, and atmosphere, achieving the purpose of anti-corrosion. The coating is mainly used in […]

Read moreCommon Failures of Automatic Valve

Four common failures associated with automatic valves are found at a high frequency in poorly performing control loops. These are Dead band, Stiction, Positioner overshoot, Incorrect valve sizing, and Nonlinear flow characteristic. Let’s take a closer look at each of these problems. Failure one: the valve is blocked up. The reasons are: 1. The control channel […]

Read moreFAQs in Using Valves

1. Why is the sanitary double seat valve easy to oscillate when working? For single-core, when the medium is an open type, the valve stability is good; when the medium is a closed type, the valve stability is poor. The double seat valve has two spools, the lower spool in the flow closed state, and the […]

Read moreWhat are the Common Connection Types of Valves?

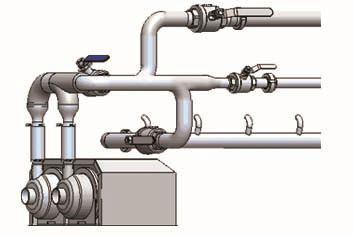

1. Flange connection This is the most used connection type of valve. According to the shape of the contact surface, it can be divided into the following subtypes: 1) Smooth type: it’s used in valves of pressure that is not high. The processing is rather convenient. 2) Concave and convex type: the operating pressure is […]

Read moreLarge Diameter Sanitary Butterfly Valve Leakage Reasons

Large-caliber sanitary butterfly valve leakage sometimes occurs during use. Due to the large diameter butterfly valve size being relatively large, so it is time to pay special attention to the installation and maintenance. So what are the reasons for large diameter sanitary butterfly valve to leak? It has two aspects. 1. Butterfly valve itself quality […]

Read moreThe Proper Ways to Clean the Filth of Hydraulic Valve

Many users don’t have problems with the use of hydraulic valves. But they don’t have a clue about the subsequent maintenance and cleaning. Here is the introduction to the cleaning technology of hydraulic valves. How do you clean hydraulic valves? Note the following when we do the cleaning Filth of the Hydraulic Valve: 1. For […]

Read more