Category: Valve Operation

The Working Temperature Range of the Valve Rubber Seals

Owners of various food industries and those who work there have a better understanding of the thermal conditions that surround such places. The sanitary valves used in such places should therefore have rubber seals that can withstand a wide temperature range. When buying rubber seals for these valves, it is good to understand various thermal requirements in […]

Read moreThe Problem of High Noise Level of Valves

One of the most obvious and uncomfortable problems with valves is noise. For human beings, noise can not only interfere with life but also lead to permanent hearing loss and an unsafe working environment. Studies have shown that long-term exposure to high levels of noise will cause damaged hearing in human beings. Hearing damage is […]

Read moreMaintenance of the Sanitary Pump

The review of sanitary pump repair records and MTBF is of great importance to responsible and conscientious pump users. For convenience, these failure statistics are often translated into MTBF (in this case, the installed lifetime before the failure). Unplanned maintenance is often one of the most important property costs, and failures of mechanical seals and […]

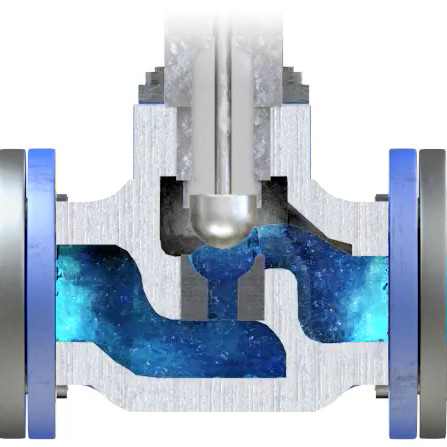

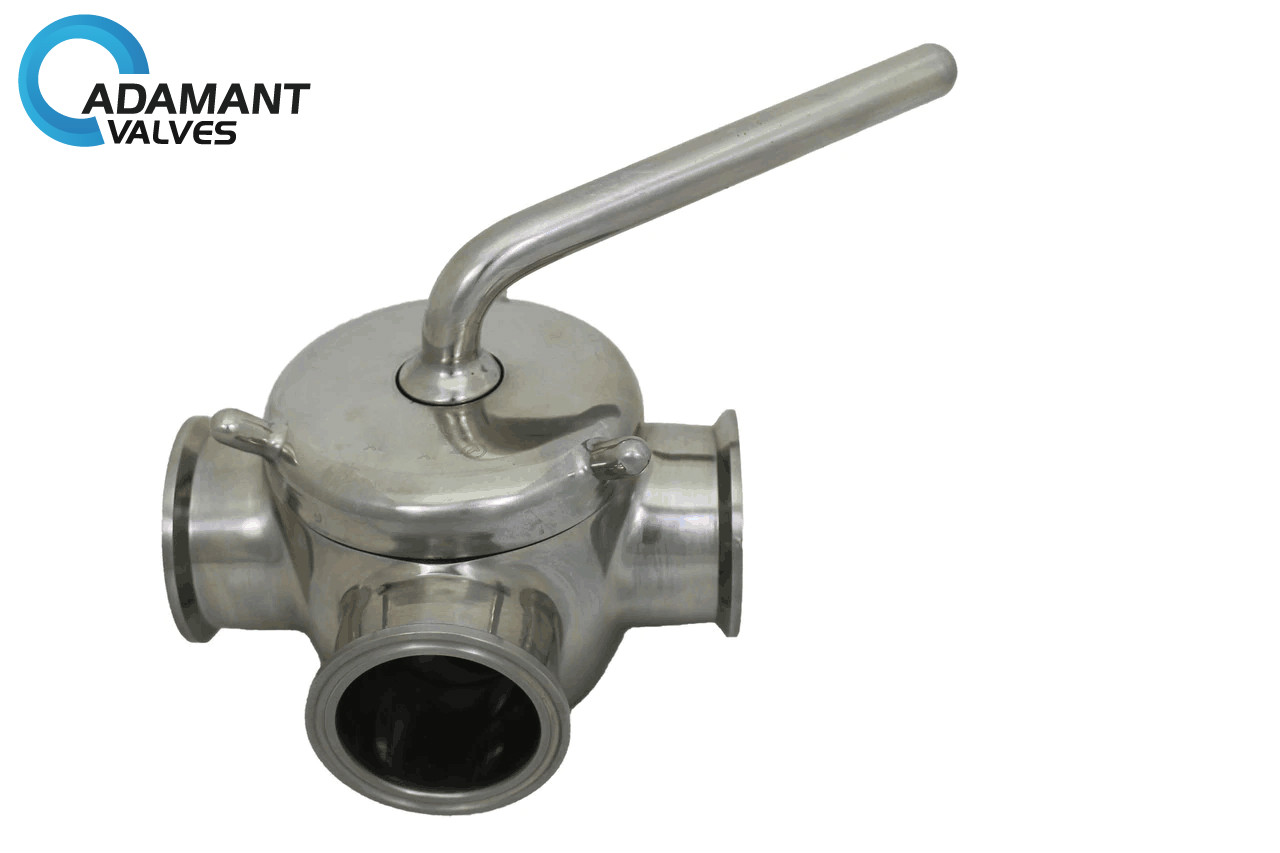

Read moreValves Components and Operating Principle

As a common piece of equipment in fluid processing facilities, sanitary valves are different in types, shapes, and sizes. However, they all basically consist of some of the parts defined as follows: Body: the framework that holds everything together and serves as the pressure boundary. Bonnet: the cover on the valve body. During valve manufacturing, the […]

Read moreThe Features of Manufacturing Technique of Valves

Compared with other manufacturing techniques, the manufacturing technique of sanitary valves has the following features: 1. The manufacturing and inspection techniques of the valve blank are more complex The casting blank of the valve is a structurally complex thin-walled shell piece. The castings require a smooth surface, and clearly cast words. In order to meet the […]

Read moreWorking as a Pipefitter in North America

A pipefitter is an artisan who installs, assembles, manufactures, maintains, and repairs mechanical piping systems. Pipefitters usually start as helpers or apprentices. The companion pipefitters deal with industrial/commercial/marine piping and heating/cooling systems. The typical industrial process pipe is under high pressure, requiring metals such as carbon steel, stainless steel, and many different metals fused together […]

Read moreSeat Leakage Classifications for Sanitary Valves

When selecting or operating sanitary valves, the seat leakage is a very important consideration that you shouldn’t skip. To have a better understanding of this factor, it’s a must to know some relative terms and definitions: Seat Leakage: the quantity of test fluid passing through an assembled valve in the closed position under the test conditions as […]

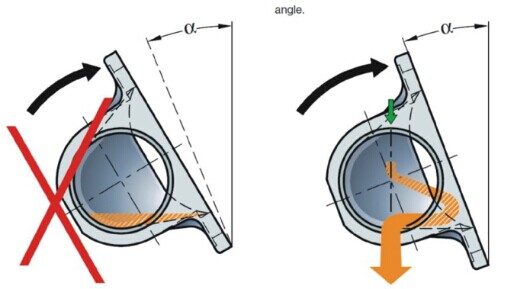

Read moreWhat Cause The Valve Sealing Surface Damage?

The sealing surface of the regulating valve is one of the most important working surfaces of the valve. Whether the material selection is reasonable and its quality directly affects the function and service life of the sanitary regulating valve. As the use of regulating valve is very wide, the working condition of the sealing surface varies […]

Read moreFunctioning Mode of Pilot-operated Sanitary Relief Valves

How do pilot-operated relief sanitary relief valves work? The pressure of a pilot-operated sanitary relief valve is provided on the upstream side (the system being protected) at the dome often by a small pilot tube. The downstream side is the pipe or open-air where the PORV directs its exhaust. The outlet pipe is usually larger […]

Read moreCommon Causes of Valve Sealing Failure and Leakage

Sanitary valves are control components that provide diversion, cut-off, throttling, check, diversion or overflow, and pressure relief in pipeline fluid conveyance systems. Valve sealing is a critical factor when safely processing and transporting fluids and gases. Even a small valve seal failure or a slowly dripping valve leak can quickly lead to a catastrophic flood, […]

Read more