Category: Sanitary Fitting

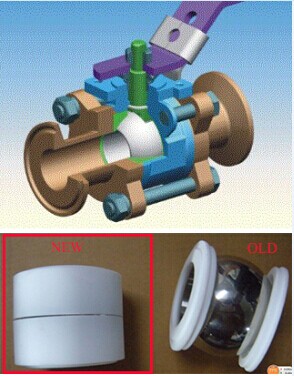

How to Extend the Life of Valves and Fittings?

Preventive maintenance is the best way to extend the life of valves and fittings. When making repairs on more sophisticated valve types, you should use the available manufacturer’s technical manuals. As soon as you observe a leak, determine the cause, and then apply the proper corrective maintenance. Maintenance may be as simple as tightening a […]

Read moreFactors Affecting Prices of Sanitary Fittings

What are sanitary fittings? Sanitary fittings are designed and constructed for use in food, beverage, medical, pharmaceutical, and biological applications where cleanliness and sterility are required. These types of fittings are constructed of materials that ensure a sterile environment and maintain sterility during use. Factors Affecting Prices of Sanitary Fittings Each mechanical procedure whether it […]

Read moreSanitary Elbow Overview

What is a Sanitary Elbow? A sanitary elbow is a kind of sanitary fitting installed between two lengths of pipe or tubing to allow a change of direction. While these corner fittings are usually a 90° or 45° angle, 22.5° elbows are also available. The ends may be machined for butt welding, threaded, or socketed. […]

Read moreTen Principles of Sanitary Fittings Design

The 10 commandments of sanitary design principles were created when the North American Meat Institute (INAM) identified research related to the elimination of Listeria as one of its top priorities in 2001 for developing sanitary fittings design principles for equipment that meet the expectations of the meat and poultry industries. Establishing industry-wide specifications benefits the entire […]

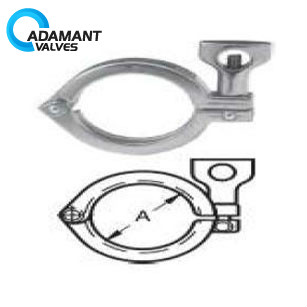

Read moreHow to Measure a Sanitary Fitting?

What Are Sanitary Fittings? Flange fittings are generally used for connections to valves, inline instruments, or equipment nozzles. Two surfaces are joined tightly together with threaded bolts, wedges, clamps, or other means of applying high compressive force. Although a gasket, packing, or O-ring may be installed between the flanges to prevent leakage, it is sometimes […]

Read moreMaintenance Methods of Sanitary Fittings

Sanitary fittings are mainly used for hygienic fittings used in places with high hygienic standards in pharmaceutical, food and other industries. Generally, sanitary fittings are purchased from pharmaceutical or food factory for maintenance and related equipment configuration, and buyers are mainly pharmaceutical, food equipment system integrators and buying wholesale and so on. Generally, sanitary fittings can […]

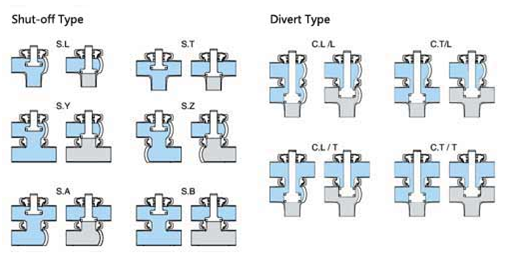

Read moreWhat is a Sanitary Tee?

What are Sanitary Tees? Sanitary tees are t-shaped sanitary pipe fittings used in the branch pipe of the main pipeline. Under normal use, sanitary tees connect a branch line to a vertical drain line or vent line. Sanitary tees can be made with a consistent diameter or different diameters to connect to pipes or valves […]

Read moreSanitary Fittings Used in Environmental Protection

Stainless steel sanitary fittings are important materials used in industry, which are characterized by variety and ease of application. Stainless steel sanitary fittings are hollow long circular steels that are widely used in petroleum, chemical industry, medical treatment, food, light industry, mechanical instrument, and other industrial pipeline and mechanical structural parts. In addition, the stainless steel […]

Read moreTaps as Sanitary Fittings in Bathrooms

Water for baths, sinks, and basins can be provided by separate hot and cold faucets; this is common in older installations, especially in public toilets/washrooms and service rooms/laundries. In kitchens and bathrooms, mixers are commonly used. In this case, the hot and cold water from both valves is mixed before reaching the outlet, allowing the […]

Read moreWelding Measures of Sanitary Fittings

High-temperature crack The high-temperature cracks mentioned here refer to the cracks related to welding. High-temperature cracks can be roughly divided into solidification cracks, microcracks, HAZ (heat affected zone) cracks and reheating cracks. Low-temperature crack Low-temperature cracks sometimes occur in martensitic stainless steel and ferritic stainless steel with martensitic structure locally. Since the main causes are […]

Read more