Author: root

Sanitary Security And Inspections For Food Industry

Consumers should never lose awareness of the sanitary threats brought by convenience foods and drinks. Some convenience stores may be carried and sold food improperly prepared or even expired, which will probably bring the consumers serious physical upset and disorder. There are definite and specific sanitary standards for every step during food and beverage preparation. […]

Read moreMaterials and handling requirements for food industry

In the sanitary fluid processing industry, besides the various requirements on equipment, there are also some regulations for products materials and handling that deserve special attention. The products materials include water, raw food materials and non-food chemicals; the products handling include transit, storage and other processes. Water In the food industry, water should be supplied […]

Read moreDesign and Construction for Sanitary Fluid Processing Equipment

Sanitary Construction and Installation Besides the designing requirements on materials and contact surfaces, sanitary fluid processing equipment should also allow for easy cleaning and inspection. All the contact surfaces should be free of sharp corners and crevices to avoid potential hold up of materials or solutions. The whole system should comply with the cleaning-in-place (C.I.P.) standard for […]

Read moreDesign and Construction for Sanitary Fluid Processing Equipment

Applying sanitary design principles to the equipment used in factories allows companies to provide food to consumers in the safest manner possible, which in turn helps them avoid costly PR disasters that arise when contaminated products make it to the public. Surfaces Properties All the contact surfaces should be resistant to corrosive food products and […]

Read moreDesign and Construction for Sanitary Fluid Processing Equipment

It’s known to all that in the food and beverage industry, nothing is so critical as sanitation and safety. This requires that the whole set of sanitary fluid processing equipment, including sanitary valves, fittings, pumps, and other pieces, be designed, fabricated, constructed, and installed according to sound sanitary design principles. Equipment that does not meet basic sanitary design principles, […]

Read moreSeat Leakage Classifications for Sanitary Valves

When selecting or operating sanitary valves, the seat leakage is a very important consideration that you shouldn’t skip. To have a better understanding of this factor, it’s a must to know some relative terms and definitions: Seat Leakage: the quantity of test fluid passing through an assembled valve in the closed position under the test conditions as […]

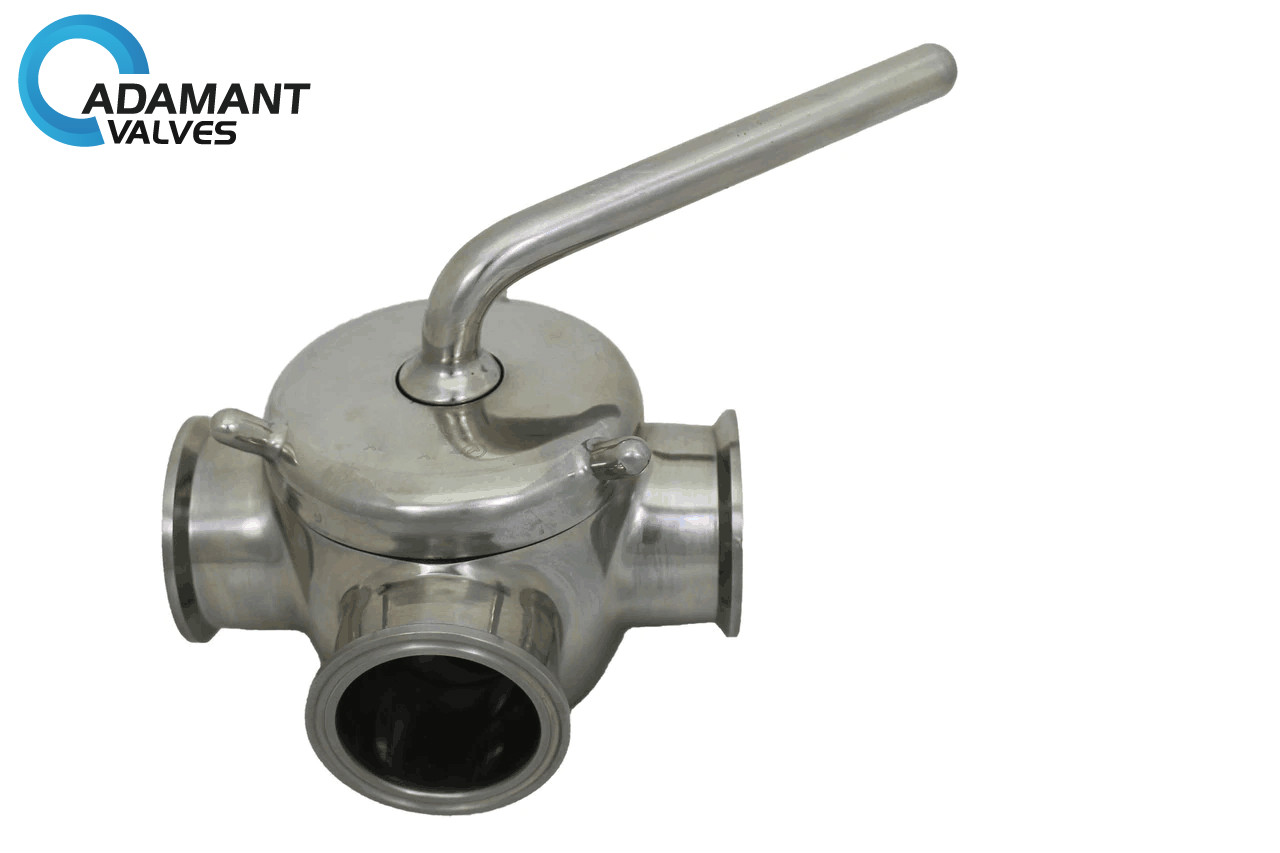

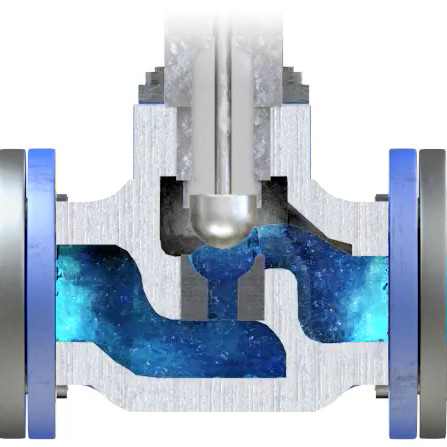

Read moreValves Components and Operating Principle

As a common piece of equipment in fluid processing facilities, sanitary valves are different in types, shapes, and sizes. However, they all basically consist of some of the parts defined as follows: Body: the framework that holds everything together and serves as the pressure boundary. Bonnet: the cover on the valve body. During valve manufacturing, the […]

Read moreHow to Extend the Life of Valves and Fittings?

Preventive maintenance is the best way to extend the life of valves and fittings. When making repairs on more sophisticated valve types, you should use the available manufacturer’s technical manuals. As soon as you observe a leak, determine the cause, and then apply the proper corrective maintenance. Maintenance may be as simple as tightening a […]

Read morePacking Failures and Troubleshooting for Sanitary Pumps

Why Packing Fail Generally, the packing of a sanitary pump fails for two reasons: normal deterioration and improper usage (usually considered as premature failure). Normal Deterioration Packing is designed to wear and tear due to pressure and lubricant consumption. With normal usage, a portion of lubricant in the packing material would lose. This is normal […]

Read moreRFID Tags Ensure Food Quality and Sanitation

In the food industry, nothing is more important than sanitation and safety. To ensure this, manufacturers should use qualified equipment, including pipelines, sanitary valves, sanitary fittings, pumps, etc., follow the Good Manufacturing Practices and other relative regulations for food safety. However, qualified manufacturing is not all. It is equally important a proper handling and transport, which has long […]

Read more