Author: root

The Advantages of Sanitary Pneumatic Butterfly Valve

Sanitary pneumatic butterfly valve uses standard electronic polish, smooth surface to ensure clean and has no media accumulation area that will not produce potential pollution. It can be quickly disassembled with fast and easy maintenance as well as uninstallation. Moreover, its downtime is quite short. It is widely used in food, pharmaceutical, cosmetics, clean steam, alcohol, […]

Read morePneumatic Ball Valve Common Faults

Symptom 1: Sanitary Pneumatic ball valve unable to operate Checking items: 1. Check the status of the solenoid: whether the coil is burned or the solenoid valve core gets stuck. 2. Perform a separate air supply test on the pneumatic actuator to check that the seal and cylinder are damaged. 3. Check if there is any foreign […]

Read moreHow Do You Fix a Leaking Ball Valve?

Leakage of Ball Valve Stem and Remedy From time to time, sanitary ball valves can leak from the valve stem no matter how well you care for them. If you find a leaking ball valve in your piping system, you’ll need to find the root cause of the stem leakage in order to troubleshoot and […]

Read moreThe Advantages of Ball Valve

The Sanitary Ball valve evolved from the plug valve, and its opening and closing pieces are a sphere. It uses the ball around the stem axis of rotation at 90 °, to achieve open and close. The ball valve in the pipeline is mainly used to cut off, distribute and change the direction of medium flow. Designed as […]

Read moreFAQs in Using Valves

1. Why is the sanitary double seat valve easy to oscillate when working? For single-core, when the medium is an open type, the valve stability is good; when the medium is a closed type, the valve stability is poor. The double seat valve has two spools, the lower spool in the flow closed state, and the […]

Read moreThe Features and Performance of Butterfly Valve

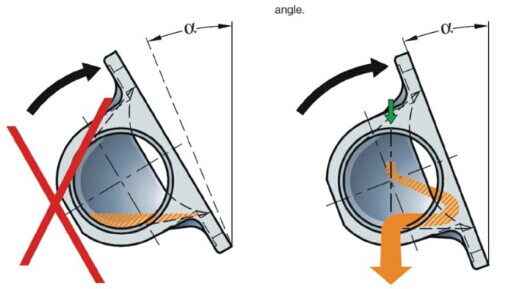

What is a Butterfly valve? Butterfly valve is a kind of valve whose opening and closing member (valve flap or butterfly plate) is a disc, which rotates around the valve shaft to achieve opening and closing. It is mainly used in the pipeline for shutting off and throttling. From the state of being fully open […]

Read morePressure Testing Methods for Gate Valves

What is a Gate Valve? Gate valves are commonly used valves that completely shut off fluid flow by moving a gate-like barrier into the pipeline path, creating a powerful seal. In the fully open position, gate valves completely remove the gate from the fluid path, which runs straight through the valve causing very little to […]

Read moreThe Application of Balance Valve

What is the use of a balancing valve? Balancing valves are throttling devices designed to regulate the fluid flow through hydronic components. In hydronic systems (HVAC systems that use water as a medium to heat and cool areas of the facility), they facilitate the distribution of heated or chilled water to all terminals. The Application […]

Read morePressure Testing Methods for Diaphragm Valves

How Do Diaphragm Valves Work? Sanitary diaphragm valves use a flexible diaphragm made of soft materials that separate the valve body cavity from the valve cover cavity. Diaphragm valves provide on/off throttling and bi-directional flow. They control flow rates by reducing or increasing the area that fluid can pass through. Performing various pressure testing methods […]

Read moreThe Pressure Testing Methods for Plug Valve

Plug Valve Mechanism: A plug valve is a kind of sanitary valve that uses holed plug as its opening and closing member. The plug rotates with the valve stem to achieve the opening and closing movements. The plug valve uses a mechanism that rotates between the open and closed positions and protects both seals from the flow […]

Read more