AV-13R Sanitary Rotating Spray Ball

Technical Specifications:

Material:304/316L Stainless Steel

Spray pattern: 360°

Sanitary Rotating Spray Ball Description:

A rotating nozzle of Sanitary Rotary Cleaning Ball uses a cleaning agent to thoroughly clean and sprays the tank. Because this device uses less detergent at low pressure, it is an effective alternative to traditional fixed spray balls. The use of double ball bearings in the swivel head makes this range of cleaning balls.

Sanitary Rotating Spray Ball Application:

Sanitary Rotary Cleaning Ball is suitable for all sanitary and industrial cleaning applications, including all sanitary and industrial grades cleaning tasks such as tanks, reactors and vessels.

Sanitary Rotating Spray Ball Working principle:

The cleaning liquid rotates the cleaning ball nozzle by its own power, and the fan-shaped jet forms a vortex in the entire reaction tank of the storage tank, thereby effectively removing the residual product remaining on the surface of the container to achieve the cleaning effect.

Sanitary Rotating Spray Ball Design standards:

The cleaning ball series are in compliance with DIN, 3A, SMS, ISO/IDF and other production standards.

Sanitary Rotating Spray Ball Technical Specifications:

Material:304/316L Stainless Steel

Spray pattern: 360°

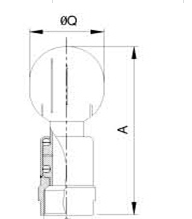

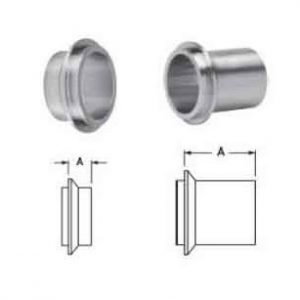

Threaded:

|

Size | A(mm) | Q(mm) | Kg |

| 1″ | 140.0 | 53.0 | ||

| 1 1/4″ | 160.0 | 63.0 | ||

| 1 1/2″ | 170.0 | 63.0 | ||

| 2″ | 192.0 | 76.0 | ||

| 2 1/2″ | 220.0 | 91.0 | ||

| Technical parameter | ||||

| Size | Pressure(bar) | Cleaning radius (m) | 360″/180″ Fluxation m3/h | |

| 1″-1.5″ | 2.0 | 1.25 | 12 | |

| 2″ | 2 | 1.5 | 38 | |

| 2.5″ | 2 | 1.0 | 38 | |

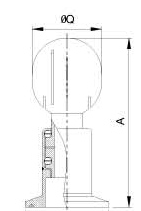

Clamped:

|

Size | A(mm) | Q(mm) | Kg |

| 1″ | 138.0 | 53.0 | ||

| 1 1/4″ | 138.0 | 53.0 | ||

| 1 1/2″ | 138.0 | 53.0 | ||

| 2″ | 168.0 | 63.0 | ||

| 2 1/2″ | 190.0 | 76.0 | ||

| Technical parameter | ||||

| Size | Pressure(bar) | Cleaning radius (m) | 360″/180″ Fluxation m3/h | |

| 1″-1.5″ | 2 | 1.25 | 12 | |

| 2″ | 2 | 1.5 | 38 | |

| 2.5″ | 2 | 2.0 | 38 | |

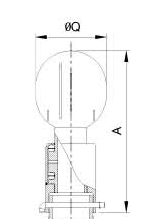

Bolted:

|

Size | A(mm) | Q(mm) | Kg |

| 1″ | 135.0 | 53.0 | ||

| 1 1/4″ | 137.0 | 63.0 | ||

| 1 1/2″ | 137.0 | 63.0 | ||

| 2″ | 168.0 | 67.0 | ||

| 2 1/2″ | 190.0 | 76.0 | ||

| Technical parameter | ||||

| Size | Pressure(bar) | Cleaning radius (m) | 360″/180″ Fluxation m3/h | |

| 1″-1.5″ | 2 | 1.25 | 12 | |

| 2″ | 2 | 1.5 | 38 | |

| 2.5″ | 2 | 1.0 | 38 | |

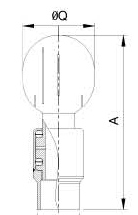

Welded:

|

Size | A(mm) | Q(mm) | Kg |

| 1″ | 143.0 | 53.0 | ||

| 1 1/4″ | 145.0 | 53.0 | ||

| 1 1/2″ | 145.0 | 53.0 | ||

| 2″ | 180.0 | 63.0 | ||

| 2 1/2″ | 200.0 | 76.0 | ||

| Technical parameter | ||||

| Size | Pressure(bar) | Cleaning radius (m) | 360″/180″ Fluxation m3/h | |

| 1″-1.5″ | 2 | 1.25 | 12 | |

| 2″ | 2 | 1.5 | 38 | |

| 2.5″ | 2 | 1.0 | 38 | |

| Technical Parameters | |||

| Steel material | Product wetted steel parts | AISI 304 or 316L | Provided with material inspection report |

| (1.4306 / 1.4404) | |||

| Other steel parts | AISI 304 | ||

| Pressure | Working pressure | ≤145psi (10bar) | |

| Supply pressure for air actuator | 70 ~ 116psi (5 -8bar) | ||

| Surface treatment | Inside surface treatment | Ra 16 ~ 32µin (0.4 – 0.8µm) | |

| Outside surface treatment | Ra 32 ~ 64µin (0.8 – 1.6µm) | ||

Reviews