How Does A Sanitary Check Valve Work?

What Is a Check Valve?

A check valve is a valve that normally allows fluid (liquid or gas) to flow through it in only one direction. Sometimes called a “one-way valve” or “non-return valve,” check valves are primarily designed to prevent backflow by using the force of the medium’s flow to automatically engage and disengage the stopping mechanism. It is a type of two-port valve. In other words, it has two openings in the body, one for fluid to enter and the other for fluid to leave. Check valves are usually relatively small valves with a simple and cost-effective design. They open and close automatically — most are not controlled by a person or any external controls (there are some exceptions). Accordingly, most do not have a valve handle or stem. The bodies (external shells) of most check valves are made of plastic or metal. Still, check valves are available in other construction materials. In some industries which have high requirements on the cleanliness of the fluid medium, sanitary check valves are preferred.

What Is a Sanitary Check Valve?

Sanitary check valves prevent pipeline backflow contamination in manufacturing processes with high hygiene standards. The main difference between sanitary check valves and ordinary check valves are the design and materials. Sanitary valves are designed for use in applications requiring clean or sterile processing. They are commonly used in dairy, food, pharmaceutical, medical, and chemical applications. Their common features include easy cleaning, crevice-free, and polished contact surfaces. The part of the valve in contact with the medium is usually made of 304SS or 316 stainless steel, which is non-toxic and corrosion-resistant.

How Do Sanitary Check Valves Work?

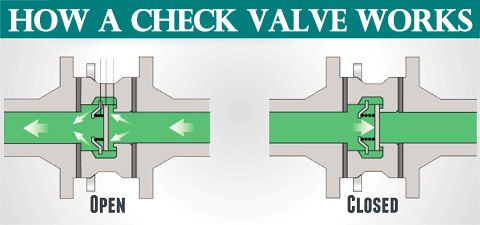

How a Check Valve Works

The structure of a check valve is usually very simple, including parts such as a valve body, a valve seat, a valve disc, and a cover. The working principle of the check valve is to allow one-way flow and automatically prevent reverse flow. This type of valve is sensitive to flow and relies on the medium to open and close the valve seat. The inner disc allows the medium to flow forward, thereby forcing the valve to open. Then the flow reverses and the valve is closed. The check valve is one of the few fully automated valves that can be circulated automatically without manual intervention.

What Are the Two Types of Check Valves?

The two most common types of check valves are swing check valves and lift check valves. The swing check valve has a hinge mechanism and a door-like disc. In order to ensure the valve clack can reach the proper position of the valve seat surface every time, the valve clack is designed in a hinge mechanism so that the valve clack has enough space for rotation and makes the valve clack truly and comprehensively contact the valve seat. The valve clack can be made of metal, or inlaid with leather, rubber, or synthetic covering, depending on the performance requirements. When the swing check valve is fully opened, the fluid pressure is almost unimpeded, so the pressure drop through the valve is relatively small.

The valve disc of the lift check valve is located on the sealing surface of the valve seat on the valve body. Aside from the manually-operated disc, the rest of this valve is like a shut-off valve. The fluid pressure lifts the disc from the seat sealing surface, and the backflow of the medium causes the disc to fall back onto the seat and cut off the flow. According to the conditions of use, the valve disc can be an all-metal structure, or it can be in the form of inlaid rubber pads or rubber rings on the disc holder.Like a shut-off valve, the passage of fluid through a lift check valve is also narrow. Therefore, the pressure drop through the lift check valve is larger than that of the swing check valve, and the flow rate of the swing check valve is less restricted.

Thank you for reading this article and we hope it can help you to better understand how a sanitary check valve works. If you want to learn more about valves, we would like to advise you to visit Adamant Valves homepage for more information.