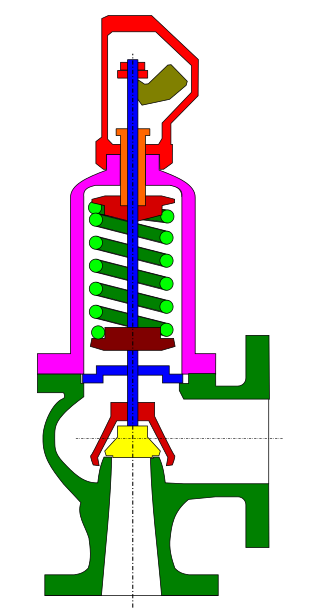

Design Features of Sanitary Safety Valves

Safety valves protect pressurized rooms or pressure vessels from an impermissible pressure increase, which can lead to damage to the connected pressure equipment.

Safety valves discharge gases, vapors, or liquids into the atmosphere or in collective pipelines when the set pressure is exceeded. Here are some design features.

The set pressure is the pressure at which the safety valve starts to open, to blow off the pressure. This pressure is fixed at the safety valve. The set pressure is subject to a tolerance (according to DIN EN ISO 4126-1) of (+/- 3%) or for valves below 3 bar of (+/- 0.1 bar).

The closing pressure is the pressure value at which the safety valve is completely closed again after it has blown off the overpressure. This value is 20% below the set pressure for liquid media (at setting pressure <3 bar, the value is 0.6 bar below).

For gaseous media, the value according to AD2000 is 10% below the set pressure and according to DIN EN ISO 4126-1 15% lower (at setting pressure <3 bar the value is 0.3 bar below the setting pressure).

The opening pressure is also called blow-off pressure and is the point at which the safety valve reaches the maximum lift for the required mass flow to be drained. This is at normal stroke safety valves at max. 10% above the set pressure and with full lift safety valves at max. 5% above the set pressure.

The operating pressure is the working pressure of a plant or system under normal circumstances. Ideally, the operating pressure is 5% below the closing pressure of a sanitary safety valve.