Working as a Pipefitter in North America

A pipefitter is an artisan who installs, assembles, manufactures, maintains, and repairs mechanical piping systems. Pipefitters usually start as helpers or apprentices.

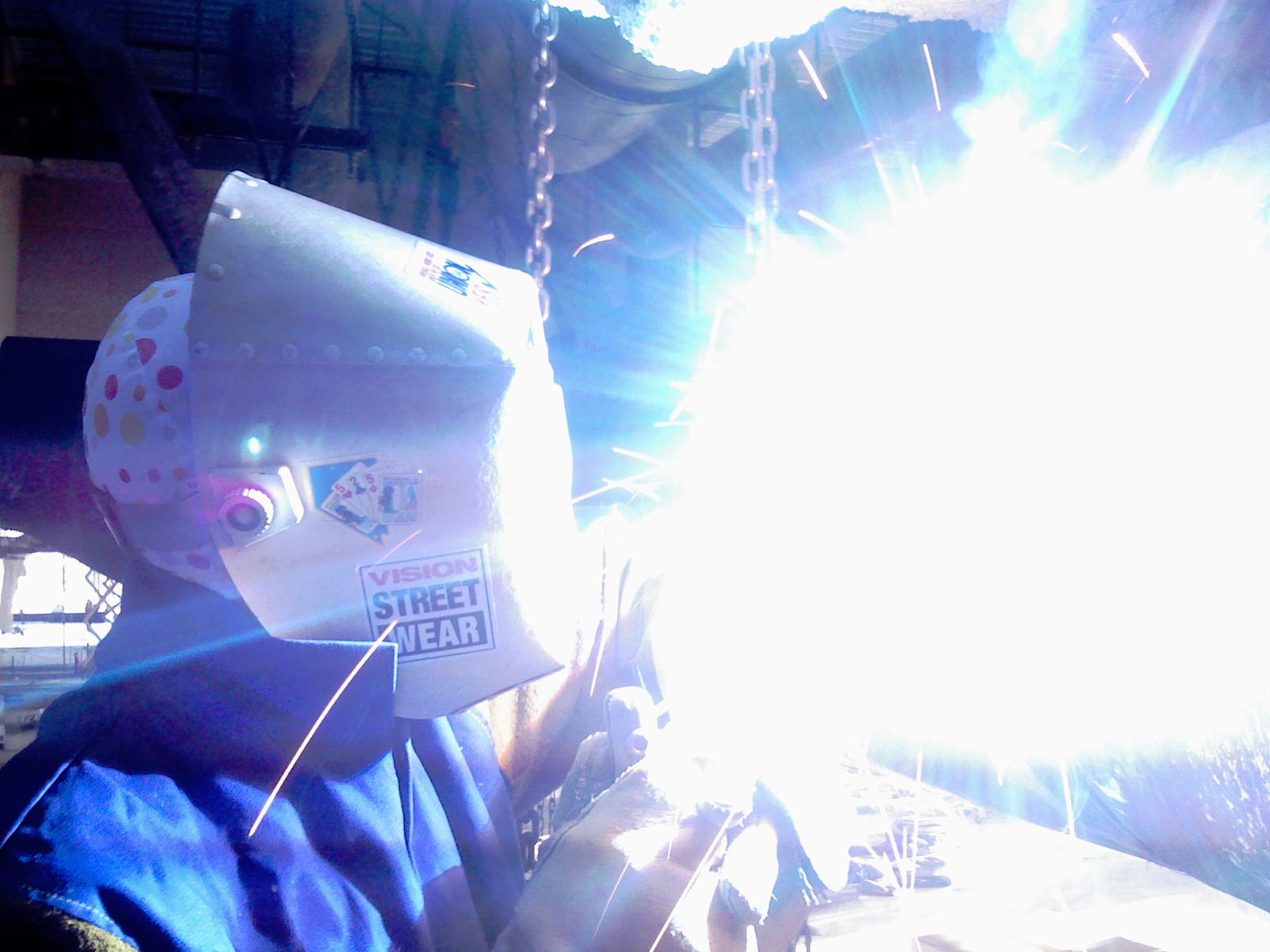

The companion pipefitters deal with industrial/commercial/marine piping and heating/cooling systems. The typical industrial process pipe is under high pressure, requiring metals such as carbon steel, stainless steel, and many different metals fused together by cutting, threading, grooving (Victaulic), bending, and precise welding.

A plumber focuses on low-pressure piping systems for wastewater and drinking water (tap water), industrial, commercial, institutional, or residential atmospheres.

Utility piping typically consists of copper, PVC, CPVC, polyethylene, and galvanized pipe, usually glued, welded, or threaded. Other types of piping systems include steam, ventilation, hydraulics, chemicals, fuel, and oil. Sanitary fittings also play roles for pipefitters.

In Canada, pipefitting is classified as a compulsory trade and carries a voluntary “red seal” of interprovincial standards. Apprentice pipefitters are provincially controlled and regulated and, in some cases, are eligible for similar trades at the end of their training.

In the United States, many states require that pipefitters be licensed. Requirements vary from state to state, but most include four to five years of apprenticeship.

Union fitters are required to pass an apprenticeship test (often called a “participation test”) before becoming a qualified journeyperson.

Others may be certified by the NCCER (formerly the National Center for Construction Education and Research).