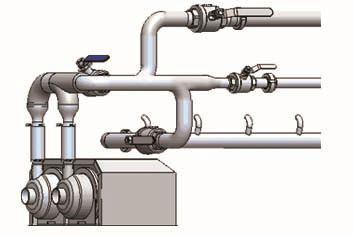

The Proper Ways to Clean the Filth of Hydraulic Valve

Many users don’t have problems with the use of hydraulic valves. But they don’t have a clue about the subsequent maintenance and cleaning. Here is the introduction to the cleaning technology of hydraulic valves.

How do you clean hydraulic valves?

Note the following when we do the cleaning Filth of the Hydraulic Valve:

1. For filth that has a long deposition time and is firmly stuck, do not scratch and damage the surface when cleaning.

2. Pay attention to safety when heating. Some inorganic cleaning solution is toxic, heating and volatilization can intoxicate people. It should be used with caution. The organic cleaning solution is flammable. Pay attention to the risk of catching fire.

3. Pay attention to the corrosiveness of the cleaning solution when choosing it, in order to avoid corrosion on the sanitary valve body.

4. After cleaning, pay attention to the storage of parts to avoid corrosion and being polluted again.

5. Assembled hydraulic valve needs to be tested before it can be put into use.

Common Cleaning Techniques of Hydraulic Valve Include:

1. Disassembly

Although various parts of the hydraulic valve are connected using bolts, the design of the hydraulic valve is not intended for disassembly. If there is no specialized equipment or professional technology, forced disassembly is highly likely to cause damage to the hydraulic valve. Therefore, we need to grasp the structure of the hydraulic valve and the connection type between parts before disassembly. When disassembling, record the position relationships between various parts.

2. Check and clean-up

Check the filth deposition situation of the valve body, valve core, and other parts. Without damaging the work surface, clean the filth using cotton yarn, brush, and non-metallic scraper.

3. Rough wash

Put valve body, valve core, and other parts on the tray of the cleaning tank. Through heated soaking, press the compressed air into the bottom of the cleaning tank. Through the stirring effect of the bubble, clean the residual filth. If conditions permit, ultrasonic cleaning can be used.

4. Fine wash

Use the cleaning solution to do high-pressure positioning cleaning and dry with the hot wind in the end. If conditions permit, companies can use existing cleaning solutions. On individual occasions, organic cleaning solutions such as diesel and gasoline can be used.

5. Assembly

Assemble according to the hydraulic valve assembly diagram or the parts assembling relationships recorded during disassembly. Be careful not to damage parts during assembly. The original sealing material is easily damaged during disassembly and should be replaced during assembly.

Conclusion

Because of the different techniques and equipment maintenance of different enterprises, service quality will vary considerably. Maintenance of equipment and technology for the lack of business, even after servicing the hydraulic system restored to its original state, should strengthen surveillance, and actively purchase spare parts, in response to an unexpected failure.

Thank you for reading our article and we hope it can help you better understand the proper ways to clean the filth of hydraulic valves. If you want to learn more about hydraulic valves, we would like to advise you to visit Adamant Valve homepage for more information.