How Many Types of Safety Valves are There?

According to its overall structure and loading mechanism, safety valves can be divided into heavy hammer lever type, spring type, and pulse type.

1. Heavy hammer lever type safety valve

Heavy hammer lever type safety valve uses heavy hammer and lever to balance the force on the valve flap. According to the principle of leverage, it can use a heavy hammer of a relatively small weight to get great force through the amplifying effect of the lever and can adjust the opening pressure of the safety valve by moving the heavy hammer (or changing the weight of the heavy hammer).

Heavy hammer lever type safety valve has a simple structure, is easy to adjust, and is rather accurate, and the load will not significantly increase due to the increase in valve flap, so it is suitable for high-temperature occasions. It used to be commonly used, especially in boilers and pressure vessels in high temperatures. But its structure is rather bulky, and the loading mechanism is prone to vibration, which often leads to leakage. Its back seat pressure is low, which makes it not easy to close or keep tight once opened.

2. Spring type safety valve

Spring type safety valve uses the force that compresses the spring to balance the force on the sanitary valve flap. The amount of compression of the helical coil spring can be adjusted by turning the regulating nut above it. The opening pressure of the safety valve can be corrected as needed by using this structure.

Spring type safety valve has a light and tight structure, and its sensitivity is relatively high, its installation location is not limited to a certain position. And because it’s not very sensitive to vibration, it can be used for mobile pressure vessels. The drawback of this kind of safety valve is that the applied load will change with the opening of the valve. That is to say, with the increase in the valve flap, the amount of compression of the spring increases, and the force on the valve flap increases accordingly. This is not good for the quick opening of the safety valve. In addition, the spring on the valve will lose elasticity due to long-term influence by high temperature. When it is used in containers with high temperatures, the issue of insulation and heat dissipation of the spring often need to be considered, which makes the structure complicated.

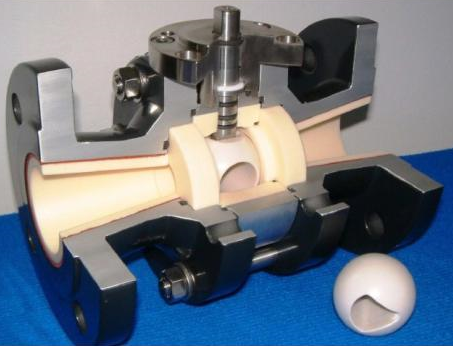

3. Pulse safety valve

Pulse safety valve consists of main valve and auxiliary valve. The main valve is driven by the pulse of the auxiliary valve. Its structure is complex. Usually, it’s only suitable for use in boilers and pressure vessels with a very large amount of safe discharge. Among the above-mentioned three types of safety valves, the spring-type safety valve is more commonly used.

Conclusion

Thank you for reading our article and we hope it can help you better understand the classification of safety valves. If you want to learn more about safety valves, we would like to advise you to visit Adamant Valve homepage for more information.